3 Bevelling machines in one unit + 3 D adaptive system =unique solution for bevelling of steels, stainless steels, hardox...

Highly efficient machine for bevelling of structural steel, stainless steel, Hardox, Weldox, Duplex and aluminium, with a unique system of both-sided bevelling and automatic feeding.- Automatic feeding with possibility of infinite feed speed adjustment within the range of 0-1.2m/min

- High speed milling tool fitted with indexabe insertes with extended lifecycle

- Maximum width of

bevelled edge by setting angle

15°/62mm (3-step machining recommended)

20°/62mm (4-step machining recommended)

25°/56mm (4-step machining recommended)

30°/52mm (5-step machining recommended)

35°/51mm (5-step machining recommended)

40°/51mm (5-step machining recommended)

45°/50mm (5-step machining recommended)

50°/51mm (5-step machining recommended)

55°/51mm (5-step machining recommended)

60°/52mm (5-step machining recommended) - Variable adjustment of required angle within the range of 15°- 60°, without the need of replacing any part

- 7-80mm material thickness

- The electric circuit is enclosed in a dust proof box, and provided with enhanced resistance to vibrations

- The machine is equipped with state-of-the-art safety elements

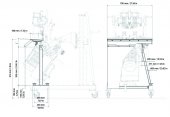

- Unique 3D manipulator

- The 3D Manipulator enables easy and fast rotation of the UZ 50 TRIUMPH machine by 180° in order to create both-sided "X" or "K" shape chamfer. Operator doesn't need crane to rotate the material = considerable time saving

- For double-sided bevel (X, K) without the need of material handling

- The machine can work upside down, no need to rotate the bevelled material

- Unique clamping system allows the beveller UZ 50 TRIUMPH assemble and disassemble within few seconds without using any tools

- Beveler UZ 50 TRIUMPH is “floating” on manipulator and compensates unevenness of the floor (unique 3D system)

- The 3D system allows the machine to adapt its operating position to the current situation at the workplace, UZ50 is floating on machined surface and compensates potential unevenness of the floor or the deformations of the material

- The quickconnect system the 3D manipulator is equipped with, offers a possibility of connecting and disconnecting the UZ50 Triumph from the manipulator in just a few seconds without the need of using any tools.This appears to be very useful in situations when the manipulator isn't able to monitor the machine due to poor quality of the work floor.The machine is then able to travel on the material

- The 3D Manipulator allows easy manipulation with the beveller

- The required height of the machine can be set up by a lift handle

- Travel is provided by massive wheels mounted on the carriage

- 3D Manipulator can be used as a stationary station

- 3D Manipulator can be used as a service station for easy maintenance of the machine

- The machine is equipped with a special table for bevelling of small size sheets to be loaded in the machine directly by hand

- ASP SYSTEM - Active intelligent overload protection; not included in the price - we recommend buying.That's a system monitoring instant load of the machine and conditions of machining.If ASP recognizes that the machine is overloaded due to tool wear, too high feed speed or incorrectly machine adjustment, the ASP system actively notifies the operator of that by flashing the pilot lights on the remote control. Should the operator fails to take steps leading to reduce the load of the machine (adjustment of the reduction size, exchange of indexable inserts, feed speed reduction), the system disconnects the power to the feed wheels and the machine stops.Caution. The system isn't protection from shock overload.ASP system can be purchased with a new machine only.

If you are not completely satisfied with one of our products you may return it any time within 30 days of the date of Sale for a hassle-free refund of the amount paid for the product. We only specify that the product not be used, damaged, missing components or manufacturer's documentation. Refunds do not include shipping costs. On exchange of defective products, BEVELLING MACHINES EUROPE s.r.o. will pay for shipping on the outbound replacement product only. Special order or non-stocking items are specifically exempted from this policy and will be assessed an appropriate re-stocking charge. Place your name and order number on the package for efficient identification, and insure all returns for your protection. Please note that we do not pay the shipping charges involved in returning goods.